HI TECH ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HI TECH ENGINEERS

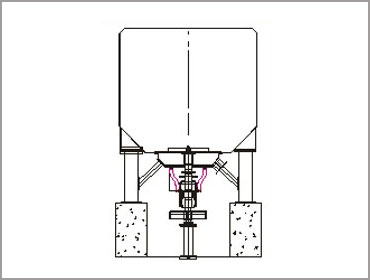

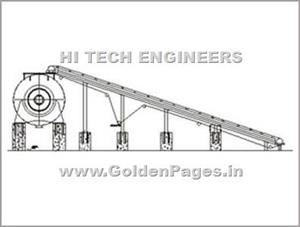

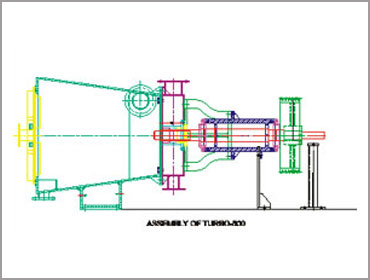

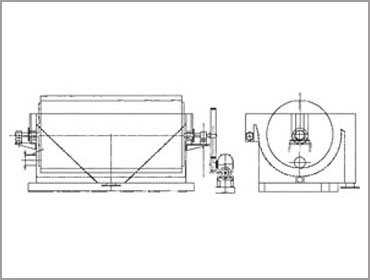

Dryer Section

Dryer Section designed to optimize the drying rate, reducing the investment cost.

M.S. Fabricated dryers up to 2.0 mt. Dia and 25 mm to 36 mm shell thickness and the width up to 5 mt.

Dryer is suitable for 4 to 5 kg/ cm2 operating pressure.

The dryers are mirror finished and the width up to 5 mt.

Our dryer system components are designed to provide best drying efficiency and uniform drying control.

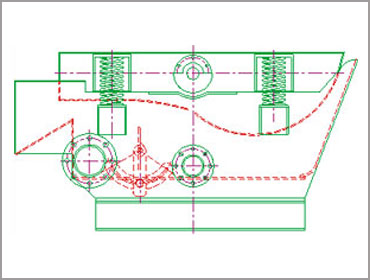

Heavy duty cast iron framing is also available its excellent for vibration dampening.

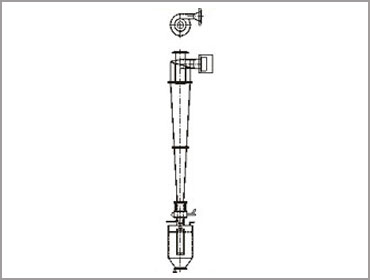

The drying cylinder can be provided with stationary syphons or inside bucket system for proper removal of condensate. (Optionally).

For high speed application above 200 m/min rope feeding arrangement is provided.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.